MAURER recently invented the 2-stage foundation seismic protection system and implemented it for the first time in the world in Mexico.

Mexico is a seismically active geographic region. The project concerns a hospital and research institute. I.e., both surgeries and special scientific research in laboratories will be performed inside. Therefore, the implementation of the seismic protection system was mandatory.

The greatest problem in this project was that the building was intended to be a 13-story structure with 4 floors of underground parking but was architecturally designed as a multi-story building on a small area (occupied by the foundation). As a result, the building would be subject to high compression and stress during earthquakes. The simplest way to avoid this was to expand the foundation of the structure. However, this significantly increased construction costs. Therefore, the customer preferred not to use this method in the project.

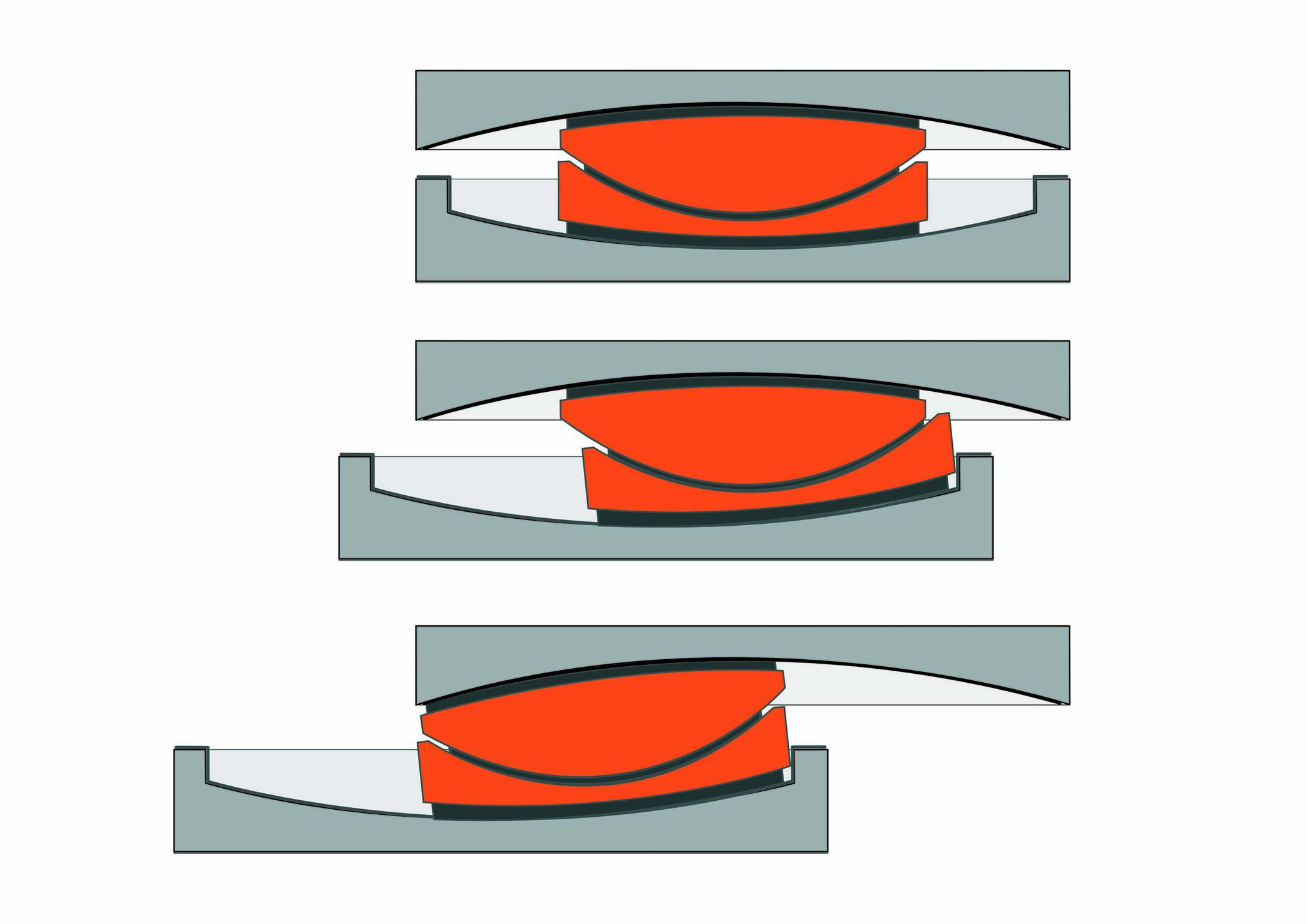

MAURER's solution was as follows: MAURER recommended implementing the newly developed SIP-A type bearing. Here, ‘A’ stands for ‘adaptive.’ As seen in the image, the bearing consists of two oval parts. During an earthquake, both parts can move independently of each other. If the earthquake (i.e., seismic) force is small, only the lower part of the bearing moves. When the earthquake intensifies, the upper part starts moving as well. This is called two-stage seismic protection. Seismic protection could have been ensured using SIP supports, but since the building, due to its purpose, required maximum protection from earthquakes (to continue surgeries and detailed and sensitive research in the laboratory), preference was given to the SIP-A model.

For the project, 34 bearings were supplied, each capable of moving in all directions by 300 mm. The service life of the bearings is 50 years.

Mexico is a seismically active geographic region. The project concerns a hospital and research institute. I.e., both surgeries and special scientific research in laboratories will be performed inside. Therefore, the implementation of the seismic protection system was mandatory.

The greatest problem in this project was that the building was intended to be a 13-story structure with 4 floors of underground parking but was architecturally designed as a multi-story building on a small area (occupied by the foundation). As a result, the building would be subject to high compression and stress during earthquakes. The simplest way to avoid this was to expand the foundation of the structure. However, this significantly increased construction costs. Therefore, the customer preferred not to use this method in the project.

MAURER's solution was as follows: MAURER recommended implementing the newly developed SIP-A type bearing. Here, ‘A’ stands for ‘adaptive.’ As seen in the image, the bearing consists of two oval parts. During an earthquake, both parts can move independently of each other. If the earthquake (i.e., seismic) force is small, only the lower part of the bearing moves. When the earthquake intensifies, the upper part starts moving as well. This is called two-stage seismic protection. Seismic protection could have been ensured using SIP supports, but since the building, due to its purpose, required maximum protection from earthquakes (to continue surgeries and detailed and sensitive research in the laboratory), preference was given to the SIP-A model.

For the project, 34 bearings were supplied, each capable of moving in all directions by 300 mm. The service life of the bearings is 50 years.