MAURER supplies expansion joints, bearings, and dampers for bridge and viaduct projects. One of MAURER’s global projects in this area is the Yarumo Blanco Viaduct in Colombia.

Construction started in 2010, but problems arose. One of the challenges was that after half of the construction was completed, it was discovered that seismic compliance had not been fully planned.

This viaduct is 640 m long and is located in hilly terrain. The geographical relief and seismic activity of the area required the strengthening of the viaduct to meet seismic standards. One of the main challenges during the strengthening phase was the height difference between the spans, ranging from 20 to 50 m depending on the terrain.

For the project, Maurer’s SIP-D-Bearings were chosen. Here, SIP stands for Sliding Isolation Pendulum, and D stands for double. The chosen bearing type should ensure four main functions:

Construction started in 2010, but problems arose. One of the challenges was that after half of the construction was completed, it was discovered that seismic compliance had not been fully planned.

This viaduct is 640 m long and is located in hilly terrain. The geographical relief and seismic activity of the area required the strengthening of the viaduct to meet seismic standards. One of the main challenges during the strengthening phase was the height difference between the spans, ranging from 20 to 50 m depending on the terrain.

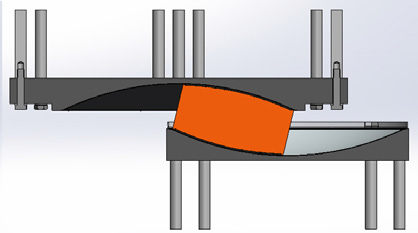

For the project, Maurer’s SIP-D-Bearings were chosen. Here, SIP stands for Sliding Isolation Pendulum, and D stands for double. The chosen bearing type should ensure four main functions:

- Isolating the bridge from the surface together with the supports and allowing horizontal displacement of up to 600 mm.

- Limiting movements with kinetic energy to 7% internal friction during an earthquake. Only Maurer could guarantee this 7% standard among alternative companies due to the patented Sliding material. The lifespan is 50 years.

- Automatically returning the structure to its original position after an earthquake.

- Transmitting vertical loads up to 14 MN.

- Stage 1: The pylons are expanded in a cubic shape from the very bottom and concreted.

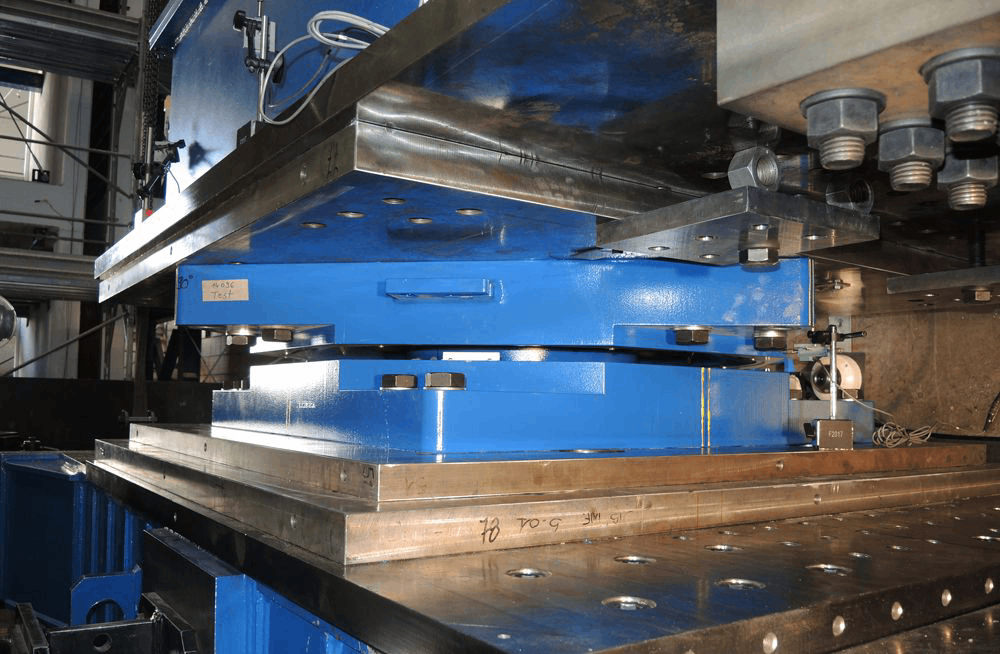

- Stage 2: Eight bearing structures and jacks are added for stability.

- Stage 3: The horizontal supports are cut from the very bottom with a diamond wire.

- Stage 4: The bridge is raised by 50 cm using four hydraulic jacks.

- Stage 5: Four SIP-D Bearings are installed on each column and secured.

- Stage 6: The supports are carefully returned to place and installed on the bearings.