Baku Tower

The project of 277 m high Baku Tower is the tallest building in not only Azerbaijan but also the entire Caucasus. MAURER installed a 400-ton inertial mass damper to protect this building from vibrations, wind, and earthquakes.

Experience

SOCAR Tower

In our country, the SOCAR Tower was one of the projects for which MAURER provided earthquake and wind protection. A 450-ton inertial mass damper was installed on the SOCAR Tower.

Experience

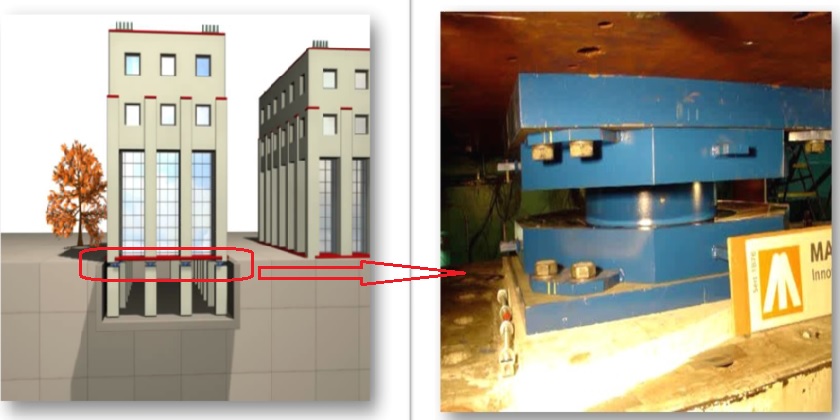

New Administrative Building of the Central Bank

In the project of the new administrative building of the Central Bank, a MAURER seismic protection system was installed for a special section. 7 spherical bearings were used.

Experience

Heydar Aliyev International Airport

MAURER supplied 39 spherical bearings for the Heydar Aliyev International Airport project.

Experience

Ahmadbayli-Horadiz-Minjivan-Aghbend

This project is part of the Karabakh Development Plan. For this project, we supplied MAURER expansion joints and elastomeric bearings.

Experience

Barda-Aghdam

One of the projects of the Karabakh Development Plan is the Barda-Aghdam motorway. For this project, we supplied MAURER expansion joints and elastomeric bearings.

Experience

Aghdam-Khindarkh

One of the projects of the Karabakh Development Plan is the Aghdam-Khindarkh motorway project. For this project, we supplied MAURER expansion joints and elastomeric bearings.

Experience

Fuzuli-Aghdam

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany) in our country. One such project is the Fuzuli-Aghdam motorway passing through the Aghdam, Khojavand, and Fuzuli regions.

Experience

Ahmadbayli-Fuzuli-Shusha

The Ahmadbayli-Fuzuli-Shusha motorway is one of the projects for which ESDESCON LLC supplied expansion joints and elastomeric bearings by MAURER (Germany).

Experience

Shukurbeili–Jabrayil–Hadrut

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany) in our country. One such project is the Shukurbayli-Jabrayil-Hadrut motorway.

Experience

Mughanli-Ismayilli-Gabala

ESDESCON LLC supplies MAURER elastomeric bearings and expansion joints for bridge projects implemented in our country. One such project is the Mughanli-Ismayilli-Gabala motorway.

Experience

Sulutapa Circle

ESDESCON LLC supplied elastomeric bearings manufactured by MAURER (Germany) for the bridge project on the motorway in the area of the Sulutape Circle.

Experience

Khirdalan Railroad Bridge

ESDESCON LLC supplied elastomeric bearings by MAURER (Germany) for the Khirdalan Railroad Bridge project.

Experience

Why should you choose us?

Our company is the official and sole representative of 148-year-old MAURER (Germany), 55-year-old KINEMETRICS (USA), 70-year-old NOE (Germany), 160-year-old DYWIDAG (Germany) and 37-year-old SHINDO (South Korea) in Azerbaijan.

Years of experience

We offer perfect project solutions based on the many years of experience of the companies we represent.

Ongoing Support

We provide regular maintenance services for all our projects.

Qualified experts

Experts in their fields from the companies we represent offer perfect project solutions.

Professionalism

Our professionalism is based on many years of experience in the appropriate field.

Safety

The solutions we offer ensure maximum safety for all structures.

Compliance with quality standards

The companies we represent hold dozens of patents in their respective fields. Our products meet global standards.

International representations

ESDESCON LLC is the exclusive representative of MAURER (Germany), DYWIDAG (Germany), KINEMETRICS (USA), NOE (Germany), and SHINDO (South Korea) in Azerbaijan.

Esdescon LLC

About the company

One of the key areas of activity of our company is the provision of seismic protection for all types of construction projects and the installation of seismic monitoring systems for such projects. We can implement seismic protection systems for individual residential homes, villas, schools, administrative and office buildings, hospitals, high-rise buildings, towers, and other structures (wind turbines, flagpoles, etc.).

More

Services

All services-

Seicmic Base isolation

Seismic isolation from the foundation for residential buildings, hospitals, office buildings, hotels, schools, and other structures.

-

TMD

In tall buildings and towers, the earthquake and wind protection system is installed at the top of the building. This system is known as a TMD (Tuned Mass Damper).

-

Expansion joints and bearings for bridges

ESDESCON LLC sells MAURER (Germany) expansion joints and bearings for bridges in our country. To date, we have supplied these products for more than 100 bridge projects.

-

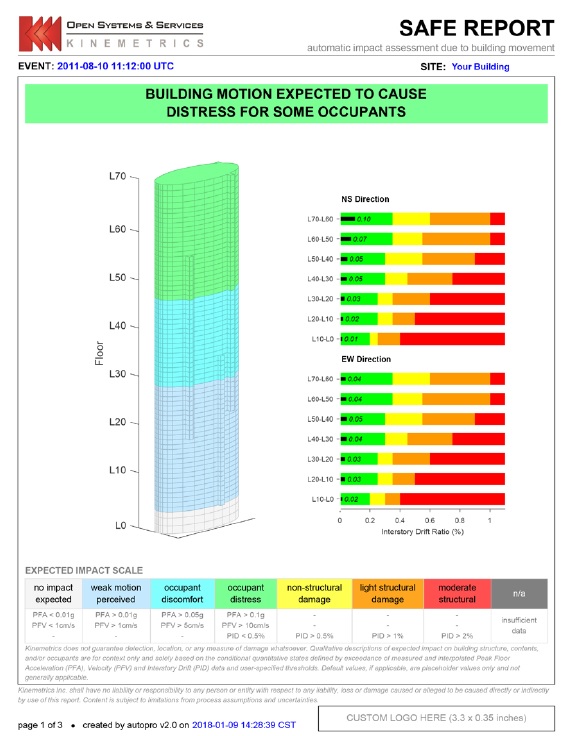

Seismic Monitoring

A seismic monitoring system can be implemented for all types of structures. This system records 24/7 all the structure vibrations (along 3 axes) in memory. Seismic monitoring systems are mainly designed in 2 versions, depending on the structure specifics and customer requirements. The first one is the simple version. Special devices are installed, e.g., on 3 levels of a residential building (at the bottom, in the middle, and at the top). All the building movements and minor vibrations are recorded in the devices' memory. The operator or engineer can download these data from the system at any time. The second option is a more complex system. The entire monitoring system is connected to a unified data center. All collected data is controlled through the system. Engineers, operators, customers, or any other persons with access to the system can enter the virtual data center and view those data. The system collects information and automatically sends prepared safety reports to authorized parties.

-

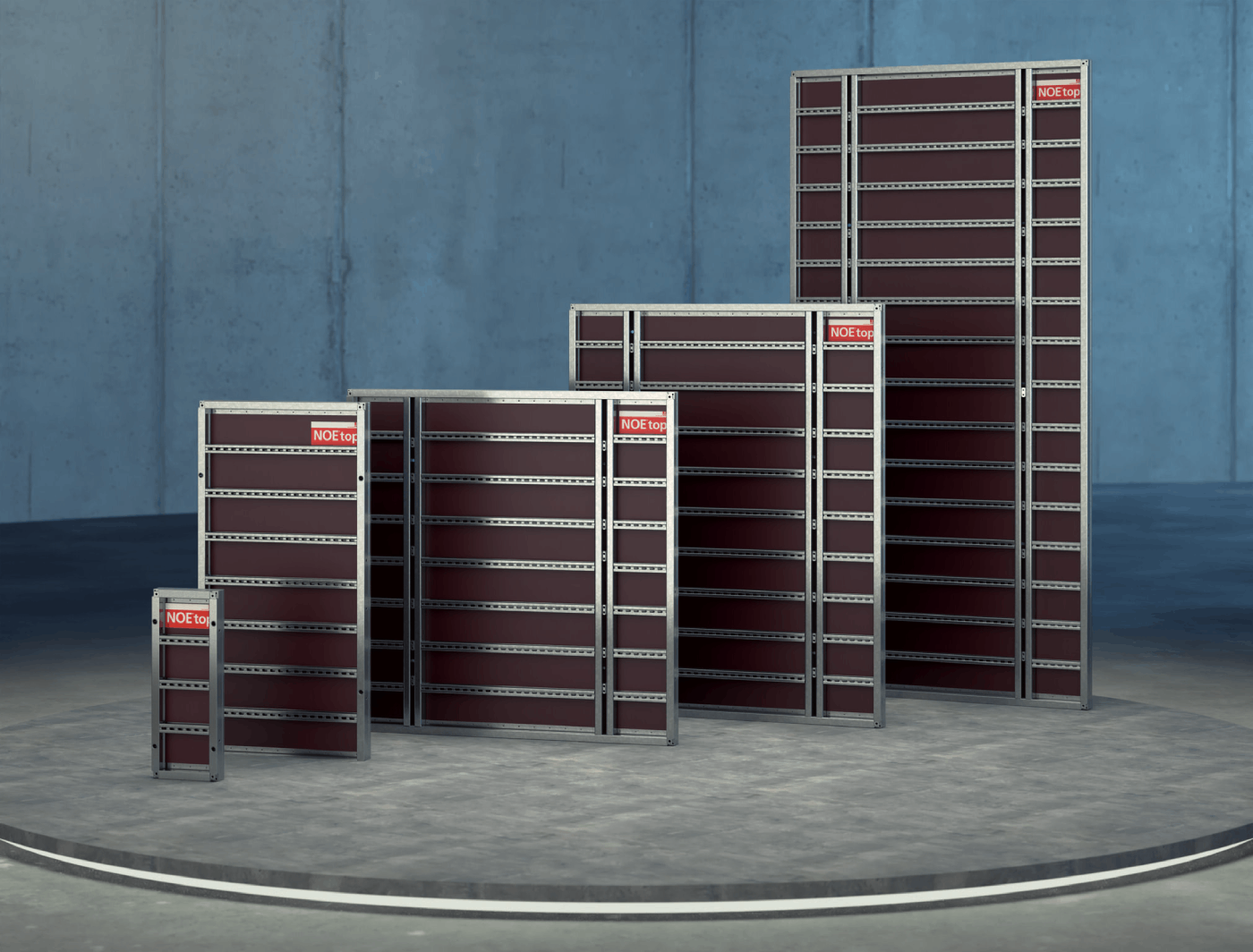

Sales and Design of Construction Formwork

ESDESCON LLC is the representative of the German company NOE in Azerbaijan. NOE is one of the leading formwork manufacturers in Germany. As the representative of NOE, we are engaged in the sale of formwork products in our country. We sell wall formwork, column formwork, circular formwork, floor formwork, wooden beams, and other formwork products.

-

Barriers and Other Road Safety Products

ESDESCON LLC is also the representative of SHINDO (South Korea) in Azerbaijan. SHINDO has been manufacturing road safety and traffic control products since 1987. The products are manufactured at 6 different plants in South Korea with a staff of over 250 employees. The products meet both European and American standards.

OUR ACTIVITY AROUND THE WORLD

We are proud that ESDESCON LLC is a representative of Germany`s Maurer, DYWIDAG and NOE, the USA`s Kinemetrics, and South Korea`s SHINDO. Our projects around the world convincingly demonstrate our professionalism in the appropriate field.

Building project

Another project in our country where a seismic monitoring system will be installed to protect against earthquakes, wind, and other factors is the new Telecommunication Tower to be built in Khojaly. ESDESCON LLC has added another significant project to its local portfolio — the new Telecommunication Tower in Khojaly, Karabakh. For this project, a seismic monitoring system manufactured by KINEMETRICS, a leading US-based company in the field, will be supplied to the main contractor, KORPU BINA TIKINTI LLC. It is worth noting that the national seismic monitoring network of the Republic of Azerbaijan was also established by KINEMETRICS.

Building project

One of the upcoming projects in our country to include seismic and wind protection systems is the new Telecommunication Tower to be built in Khojaly. ESDESCON LLC has added another project to its portfolio in Azerbaijan — the new Telecommunication Tower to be constructed in Khojaly, in the Karabakh region. To the main contractor, KORPU BINA TIKINTI LLC, a Tuned Mass Damper (TMD) produced by MAURER will be supplied to provide seismic protection for the new tower.

Tunnel project

Another project where ESDESCON LLC supplied expansion joints and bearings by the German company MAURER is the “Academician Hasan Aliyev Street – Koroglu Metro Station” highway project. To one of the main contractors of this project, KORPU BINA TIKINTI LLC, 1070 elastomeric bearings in 5 different sizes, manufactured by MAURER, were supplied. The new road is being designed and constructed parallel to Ziya Bunyadov and Heydar Aliyev avenues. According to the State Program, the section of the new road currently under construction — from Academician Hasan Aliyev Street to Muzaffar Narimanov Street — will have 6 traffic lanes and a total length of 3.9 kilometers (plus an additional 2.6 kilometers of ramps and access roads). The project also includes the construction of 4 tunnels with a total length of 2,210 meters and 3 underground pedestrian crossings with a total length of 112 meters.

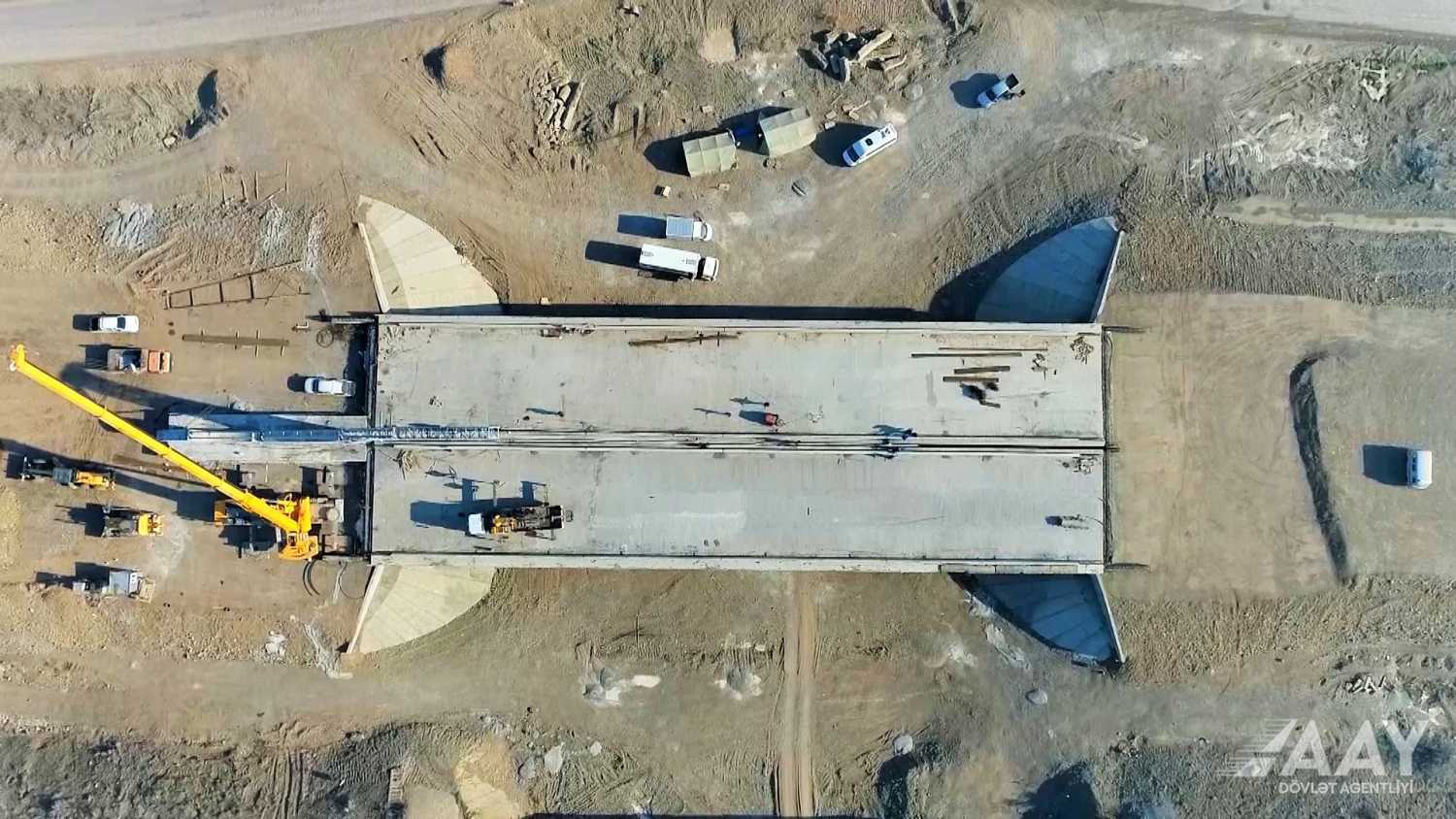

Bridge project

One of the projects in which ESDESCON LLC supplied expansion joints and bearings manufactured by the German company MAURER is the reconstruction of the Yuxarı Shirvan Canal. For one of the three contractors of the project, NORTH WEST CONSTRUCTION LLC, MAURER expansion joints were supplied for 17 bridges. Within the scope of the project, a total of 311 meters of MAURER D80 KB Expansion Joints were delivered for 17 bridges.

Building project

Another project in our country where seismic and wind protection systems have been applied is the new Flagpole at the National Flag Square. For the seismic and wind protection of this structure, ESDESCON LLC supplied a Tuned Mass Damper (TMD) system manufactured by the German company MAURER. Furthermore, the temporary dampers used during the erection of the flagpole were also produced by MAURER. The current height of the flagpole is 195 meters and consists of 10 conical metal sections. The permanent MAURER TMD is installed in the 9th section of the pole. Before construction, one of the main questions was: How can the pole be protected from wind-induced vibrations during the erection of the first 8 sections — when the permanent damper is not yet in place? To solve this, temporary dampers were planned and applied during the erection process. Since the first 3 sections were heavy and had large diameters (the base diameter of the pole is 6.45 meters) and their total height (50.508 meters) was not considered critical, structural analysis showed that temporary dampers were not necessary for these sections. However, for the erection of sections 4 through 8, temporary dampers were essential to prevent significant swaying or resonance under wind loads. As a result, temporary dampers were designed by Distributed Engineering and a 5-unit temporary damper system was manufactured at MAURER’s plant in Munich, Germany. These dampers consist of cylindrical chambers filled with liquid and metal partitions with various orifices inside, allowing them to effectively suppress vibrations during the erection of sections 4 to 8, ensuring a stable construction process. Further information about the permanent MAURER TMD system can be found on our website.

Building project

One of the projects in our country where seismic and wind protection systems have been applied is the new Flagpole at the National Flag Square. This project is not only one of the most unique projects in Azerbaijan, but also in the world. The new flagpole, which has already entered the Guinness Book of Records due to the size of the flag and was recently inaugurated by the President, is among the tallest in the world, with a height of 195 meters. For such a tall structure, a protection system against seismic and especially wind loads is one of the most critical components. As ESDESCON LLC, we supplied a 3-unit, 14-ton TMD (Tuned Mass Damper) system produced by MAURER, a 148-year-old German company we represent in Azerbaijan. This 3-stage TMD system operates depending on the intensity of the wind and seismic forces: the first stage activates under mild conditions, and stages 2 and 3 are engaged progressively as the intensity increases — thus fully ensuring the structural safety and damping vibrations of the flagpole. According to structural calculations, the theoretical sway of the top of the pole without a TMD would be ±3 meters. With the application of the TMD, this sway was practically and theoretically reduced to ±15 cm (a 20-fold reduction). One of the biggest challenges faced by MAURER in this project was the necessity to significantly modify the TMD structure due to the internal design of the flagpole, which includes an elevator and stairs at certain heights. MAURER specially designed and manufactured a ring-shaped TMD system with a hollow center for this project. The loads are distributed along the inner wall of the pole and move accordingly to ensure stability. Additionally, ESDESCON LLC supplied temporary dampers used during construction. Detailed information about these systems is available on our website.

Bridge project

ESDESCON LLC also provided expansion joints and bearings manufactured by the German company MAURER for the reconstruction of the Alat-Osmanli-Astara railway line — one of the main segments of the North-South International Transport Corridor. To the main contractor KORPU BINA TIKINTI LLC, MAURER elastomeric bearings and expansion joints were supplied for 3 highway bridges and 3 railway bridges. Within the scope of this project, over 450 MAURER elastomeric bearings in various sizes and 18 expansion joints with a total length of 251 meters were delivered.

Bridge project

Another project where ESDESCON LLC provided expansion joints and bearings by the German company MAURER is the road project in Gadabay district, which connects 15 residential areas over a 45 km road, as well as the 24.2 km Tartar-Aghdara highway. For one of the contractors of the project, GANJA KORPU TIKINTI-2 LLC, we supplied a total of 150 MAURER elastomeric bearings in two different sizes.

Bridge project

One of the projects in which ESDESCON LLC supplied expansion joints and bearings manufactured by the German company MAURER is the road construction project located in Khizi. For this project, MAURER-produced elastomeric bearings and expansion joints were supplied to the main contractor EPSILON LLC.

Bridge project

Another project in which ESDESCON LLC has supplied expansion joints and bearings from the German company MAURER in our country is the Sugovushan–Kalbajar–Aghdam highway project, which is part of the Karabakh development plan. We supplied a total of 100 MAURER-manufactured elastomeric bearings in various sizes to GANJA KORPU TİKİNTİ-2 LLC, the contractor of the project.

Bridge project

Another project in which ESDESCON LLC has supplied expansion joints and bearings from the German company MAURER in our country is the Pirshaghi–Novkhani–Khirdalan–M4 highway project, which is part of the State Program for 2025–2030 and is currently under construction by the State Agency of Azerbaijan Automobile Roads. This project involves the construction of a 29-kilometer-long highway of technical grade 1A with 6 traffic lanes. As ESDESCON LLC, we supplied a total of 220 MAURER-manufactured elastomeric bearings in different sizes for the bridges in this project to GANJA KORPU TİKİNTİ LLC, one of the project contractors.

Bridge project

One of the projects in which ESDESCON LLC supplied products for road infrastructure works, particularly for bridges, is the project where we manufactured and supplied MAURER expansion joints for our client KORPU BİNA TİKİNTİ LLC. Within the scope of this project, a total of 25 units of MAURER Expansion joint system with sinus bolted plate, with a combined length of 429 meters, were supplied. These products were used in the construction of several bridges located in the Karabakh region.

Bridge project

Another project in which ESDESCON LLC has supplied expansion joints and bearings from the German company MAURER in our country is the Salyan-Bilasuvar and Ismayilli-Muganli highways project. We supplied 700 MAURER-manufactured elastomeric bearings in 4 different sizes for the highway bridges built by KORPU BINA TIKINTI LLC, one of the contractors of the project. This project also includes the construction of a new highway bridge on the M-3 Alat–Astara–State Border with the Islamic Republic of Iran road.

Bridge project

One of the projects in which ESDESCON LLC has supplied expansion joints and bearings from the German company MAURER in our country is the road located in the Taghlar area of the Khojavend district, which is part of the Karabakh development plan. We supplied 238 MAURER-manufactured elastomeric bearings to EVRASCON OJSC, the main contractor of this road.

Road project

Strand Anchors Stabilize Excavations DYWIDAG Strand Anchors were used to stabilize various excavations in the Stuttgart 21 sub-project, specifically in Project Approval Section 1.5, which is part of the Stuttgart-Ulm railway project. The new suburban train station was built using the open cut method, and the excavations in Lot 4 North were secured with DYWIDAG Strand Anchors. Context Project Approval Section 1.5 covers the area between the Feuerbach and Bad Cannstatt train stations, as well as the access to Stuttgart Main Station. This section includes the construction of about 9km of underground long-distance and suburban rail tracks. In Lot 4, a new district is being developed by removing the existing above-ground tracks in the north of the main station, with a new suburban train station being built in the Rosensteinquartier. Solution For excavation stabilization in area UL 7 at Mittnacht Street Station, approximately 13,000m of temporary, grouted 3 to 5 strand DYWIDAG Strand Anchors were used. In area UL 8, around 9,000m of temporary and permanent 3 to 5 strand anchors were installed. Additionally, for area UL 10, about 18,000m of temporary and permanent grouted DYWIDAG Strand Anchors were supplied, ensuring the stability of the excavations throughout the project.

Road project

Stainless Steel Hollow Bar and Mesh Stabilizes Failing Slopes at Severn Estuary The Severn Estuary's frequent slope failures had caused significant disruptions to the Newport to Gloucester rail line, a key route connecting South Wales with North England. DYWIDAG supplied geotechnical materials to stabilize the slopes and prevent future closures and accidents. Context The Newport to Gloucester rail line is essential for passenger and freight traffic but has faced repeated disruptions due to slope collapses in the Severn Estuary area. In the winter of 2021, four collapses led to closures, highlighting the need for a permanent solution. Solution DYWIDAG developed a solution to stabilize the slopes, some of which reach 37m in height. The solution included installing soil nails, stainless steel mesh, and surface cover. Using stainless steel bars and mesh extended the lifespan from 60 to 120 years, minimizing future maintenance needs. The hollow bar option reduced drilling costs and time on-site, which helped minimize traffic disruptions. DYWIDAG supplied QTS with the necessary materials, including grade 316 R32-360 stainless steel hollow bars, DYWIDAG EYY drill bits, and stainless steel mesh. Abseil teams and rigs completed the installation, using air flush and secondary grouting for drilling. The project was completed on time and within budget, successfully securing the slopes.

Road project

Critical Rail Temperature Monitoring on the West Coast Mainline The West Coast Main Line (WCML), a vital UK railway connecting major cities like London, Glasgow, Birmingham, Liverpool, and Manchester, requires constant monitoring to ensure safe and continuous service. Context Due to extreme temperatures, monitoring rail temperatures during warmer months is essential to prevent rail buckling. Historically, this was done manually, with staff sent out to take live readings during high-risk weather events. Solution DYWIDAG developed the SmartTemp system, installed around the web of the rail, allowing for remote monitoring, alerting, and trending via a web login page. This system allows Network Rail (NR) to view live rail temperatures and adjust trigger temperatures via a simple phone call or email. Stuart Gordon of Network Rail noted, “What makes a difference to us is the ability to log in and view live rail temps, sending staff out only when absolutely necessary.” The West Coast maintenance team uses SmartTemp’s sensors daily, managing track safety and usage in high-risk areas. The system provides real-time data, reducing the need for operatives on live tracks and offering a comprehensive view of track conditions for safer operations.

Road project

Challenging Embankment Stabilization at Callow Hill Rail Cutting DYWIDAG provided an effective solution to stabilize an embankment at Callow Hill Rail Cutting, supporting the busy Swindon to Bristol rail line, amid challenging weather and site conditions. Context The embankment at Callow Hill Rail Cutting, located in Wiltshire, was unstable and failing, threatening the twin-track rail line. A slope stability analysis revealed the presence of cohesive soils with underlying sands and gravels. The project faced extreme weather disruptions, including hurricane-force winds from tropical storm ‘Barra,’ and required additional resources. Difficult drilling conditions, a narrow access mat, and coordination with other contractors added complexity. All work was to be carried out under rail possessions (temporary closures for maintenance). Solution A steel piled wall, combined with DYWIDAG Dywi Drill Tension Piles, was selected as the most effective solution. The retaining wall and anchoring system were installed over two weekend rail blockades. Universal Piling Ltd, DYWIDAG's specialist contractor, installed the piles using an RTG 19T telescopic leader rig, supported by a 100-ton tracked crane. The tension anchors, 18 meters long and galvanised, were installed using a Ripamonti soil nailing mast. A total of 84 tension ground anchors were added. Outcome Despite disruptions caused by Storm Barra, the project was completed on time, with all 168 sheet piles installed successfully. Richard Edlington, Programme Manager at Network Rail, commended the team's perseverance, and Francis McGarry, Investment Director, emphasized the leadership in overcoming real-world challenges to deliver the project for passengers.

Building project

DYWIDAG Consolidates Monopile Foundations at Amrumbank West Offshore Wind Park DYWIDAG successfully provided and installed post-tensioning systems to stabilize monopile foundations at the Amrumbank West wind park, addressing damage caused during the construction process. Challenge Amrumbank West, located 35 km north of Helgoland, consists of 80 wind towers and is situated in water depths of 20-25 meters. Each turbine generates 3.6 MW, providing energy to up to 300,000 households. During the installation of two monopile foundations, damage occurred at the construction joints between the lower and upper sections of the foundations. This required intervention to restore the full load-bearing capacity of these joints. Solution DYWIDAG deployed 52 Wire EX Tendons for each of the damaged monopile foundations, each 13.3 meters long, and installed them across the construction joints. The tendons were post-tensioned with a load of 4,000 kN per tendon to restore the load capacity of the joints. The tendons, totaling 35 tons, were prefabricated and adapted for the project in DYWIDAG’s facility in Langenfeld, Germany. Additional reinforcement was integrated into the anchorage area, which streamlined assembly on-site and reduced setup time. To protect against corrosion, the tendons’ sheathing was filled with a corrosion protection compound. This ensured no seawater could reach the tendons, and the same protection was applied during transportation across the North Sea. Due to the remote offshore site, additional jacks and hydraulic pumps were deployed to minimize delays. Some tendons were also equipped with DYNA Force® Sensors for precise monitoring. Outcome Despite the challenging working conditions and limited space, the project was completed successfully, restoring the structural integrity of the monopile foundations and contributing to the continued operation of the wind park.

Building project

DYWIDAG Stabilizes Huge Open Pit Mine with Soil Nails DYWIDAG provided key materials for stabilizing the steep slopes of the former Mina de Águas Claras mine in Brazil, ensuring safety and enabling future use of the site. Challenge Mina de Águas Claras, an iron ore mine in Minas Gerais, was closed in 2002 after extracting 300 million tons of ore. The deep pit, now partially filled with water, posed significant safety risks due to steep slopes prone to erosion and landslides. A 1992 landslide and ongoing erosion made the area dangerous, especially given its proximity to a densely populated region. Rehabilitation efforts had been delayed for years, but in 2013, Vale decided to stabilize the slopes. Solution DYWIDAG’s solution involved the stabilization of the highest portion of the western pit. The process began in 2014 with the removal of loose soil and the installation of a drainage system to prevent further erosion. The stabilization work was carried out step-by-step, starting from the top down. To secure the high-strength steel mesh used for slope stabilization, DYWIDAG provided 47,535 meters of GEWI Soil Nails, each 32mm in diameter and made from GR 50/55 steel. These soil nails were installed into the stable strata beneath the slope, anchoring the steel mesh. The soil nails, along with 7,310 nuts, ensured the safe installation of the mesh, which was then covered with vegetation to further protect the area. Outcome The successful stabilization project minimized the risk of landslides and erosion, ensuring the safety of the surrounding area and paving the way for the future development of the site.

Building project

DYWIDAG Develops Modern Testing Method for Structural Repair of Westpoint Dam After corrosion caused tendon failures, DYWIDAG was contracted to develop a new, more reliable tendon testing method to ensure the safety of Westpoint and Robert F. Henry dams. Challenge In the 1960s, the US Army Corps of Engineers used high-strength smooth steel tendons for trunnion girder anchorages in dams. These tendons were difficult to inspect and repair, as they lacked threads for standard testing. Following tendon failures due to corrosion, a more accurate testing method was needed. Solution DYWIDAG was contracted to perform lift-off tests to determine the tension force of the existing tendons. Using a specially developed gripping device, DYWIDAG engineers conducted load tests at a mock-up facility and tested the tendons at both dams, even in hard-to-reach areas. Out of 852 tendons at both dams, DYWIDAG successfully tested 216 tendons, providing essential data that helped the Army Corps assess the dams' condition and make informed safety decisions. Outcome DYWIDAG’s testing allowed for the identification of potential issues, ensuring the safety of the dams and enabling the Army Corps to plan necessary repairs.

Building project

DYWIDAG Supports Construction of Canada’s First Urban Wind Turbine DYWIDAG played a key role in constructing Toronto's first wind turbine, providing clean energy to the city's grid. Challenge Located near Band shell Park, the 94-meter tower generates 750 kW, producing enough electricity for 250 homes. The foundation required strong anchorage to secure the turbine against forces like wind and snow. Solution The foundation used 150m³ of concrete and 6,000 kg steel tube anchors. Eight DYWIDAG Rock Anchors, each 18m long with a 7m bond length in bedrock, secured the turbine. A three-blade turbine spins at 21 RPM atop the 30-story structure. Result Completed after overcoming several challenges, the turbine is Canada’s first urban wind energy source, helping to raise awareness about renewable energy. DYWIDAG continues to support wind energy projects like the Le Nordais wind farm.

Building project

DYWIDAG Supplies Anchors for the World’s First Hybrid Steel and Wood Wind Towers DYWIDAG helped build the first-ever hybrid wood and steel wind towers in France, a groundbreaking solution for sustainable energy. Challenge Seven wind towers were to be built on clay/limestone terrain, requiring heavy foundations. Traditional steel towers needed large, concrete-based foundations, but a hybrid approach was proposed to reduce material use and environmental impact. Solution InnoVent designed a hybrid wood-steel tower, using lighter materials and four 1m diameter, 20m deep piles instead of heavy concrete foundations. DYWIDAG supplied 64 strand anchors and performed the stressing for the first two towers. Result The innovative design, completed in June 2022, cuts material use, reduces CO2 emissions, and offers ecological benefits, creating a more sustainable wind tower solution.

Building project

Stabilization of Rock Face with Rock Bolts at Notre Dame de la Garde Basilica DYWIDAG supplied rock bolts and mesh to stabilize the unstable rock face at Notre Dame de la Garde Basilica, preserving this iconic landmark. Challenge The Basilica, located on a steep hill, faced instability due to atmospheric exposure and weathering of the rock face. A solution was needed to reinforce the slope and secure the site. Solution DYWIDAG’s local representative, SAGGAM, provided 455 DYWIDAG Gewi Rock Bolts, totaling 1,300m, along with 1,600m² of mesh. The bolts were installed by rappelling down the rock face, securing the protective mesh with post-tensioning and grout injection. Result The quick and effective stabilization preserved the rock face and ensured the safety of the Basilica, thanks to DYWIDAG's comprehensive solution.

Building project

Freedom Tower: A Symbol of Resilience and Freedom DYWIDAG provided high-quality bar anchors for the foundation of the Freedom Tower, located at Ground Zero, symbolizing freedom and resistance against terrorism. Challenge Following 9/11, the Freedom Tower was designed to stand as a symbol of resilience. The tower, with a historic height of 1,776 feet, required robust security and structural support, including a deep foundation capable of withstanding potential threats. Solution DYWIDAG supplied 65mm bar tendons and reinforcement bars for a critical 35x5x2m girder, located 30 meters above ground. This included 9 layers of tendons and 96 vertical and 168 horizontal reinforcing bars. Result The foundation of the Freedom Tower, reinforced with DYWIDAG’s high-strength materials, supports the building’s symbolic and structural significance, ensuring its longevity and resilience.

Building project

Reliable Concrete Structure for LAX Traffic DYWIDAG supplied unbonded monostrand post-tensioning to reinforce a new concrete parking structure at Los Angeles International Airport (LAX), improving traffic flow and infrastructure reliability. Challenge LAX, the second busiest airport in the U.S., faced severe parking and traffic congestion. A durable parking solution was needed. Solution DYWIDAG provided 1.2M lbs. of 0.5-inch unbonded monostrand post-tensioning for the 4,300+ stall Intermodal Transportation Facility – West (ITF-West). The project moved on a tight schedule, with DYWIDAG offering technical support and stressing equipment. Result The reinforced parking structure enhances passenger convenience and durability. LAX’s infrastructure overhaul, including the Automated People Mover train system, is set to improve overall airport accessibility.

Building project

Seismic Stability Secured: DYWIDAG Anchors the Sydney Fish Market The new Sydney Fish Market faced a critical challenge: preventing seismic uplift in its foundation. DYWIDAG provided advanced 61-strand multistrand anchors, ensuring long-term stability and safety. Key Benefits Seismic Protection – Prevented uplift, securing the foundation. Innovative Design – First use of coiled 61-strand anchors in Australia. Efficient Installation – Collaboration with geotechnical experts for a fast, safe process. Long-Term Durability – Engineered for a 100-year lifespan. Solution DYWIDAG installed 40m-long multistrand anchors into seabed rock, securing them within angled steel foundation piles. A 2,200kN hydraulic jack ensured precise tensioning. This pioneering method, adapted from dam strengthening projects in the USA, set a new benchmark in seismic engineering. Result The Sydney Fish Market now stands on a seismically resilient foundation, built to last 100 years. DYWIDAG’s innovation ensured fast, efficient, and safe installation, reinforcing its position as a leader in seismic protection solutions.

Bridge project

Precision Measuring Instrument for Stay Cable Bridge Repair The Eugene Talmadge Memorial Bridge underwent cable and damper system repairs after 15 years of service. DYWIDAG’s state-of-the-art precision measuring technology enabled the successful retrofit. Background: Originally built (1953-1954), the old Talmadge Bridge was replaced with a new cable-stayed bridge in 1991 to accommodate larger vessels. The bridge features a 185 ft (311m) vertical clearance at high tide and 1,023 ft (56m) horizontal clearance. Problem & Challenges: Urethane dampeners, placed at the base and top of each cable, suffered from continuous vibration, causing them to loosen over time. Due to temperature variations, both the cables and deck expand and contract, making damper placement highly complex. Retrofit difficulty: The new dampeners had to fit within the existing exit pipe geometry, requiring extreme precision. DYWIDAG’s Solution & Innovation: State-of-the-art measuring instruments and reverse engineering software enabled precise data collection. Robotic arms measured down to one-thousandth of an inch, ensuring exact damper fit. A 3D model was generated based on real-time measurements for fabrication and installation. Results & Impact: New dampeners were fabricated and installed within just one week. DYWIDAG’s advanced technology streamlined the measurement, production, and installation process. The Talmadge Memorial Bridge’s stability was restored, extending its service life and ensuring safe operation. This project demonstrated cutting-edge precision engineering, reinforcing DYWIDAG’s expertise in structural rehabilitation.

Bridge project

Seismic Retrofit of the Golden Gate Bridge Using Geotechnical and Post-Tensioning Systems The Golden Gate Bridge in San Francisco is located in a highly active seismic zone. Studies indicated that a magnitude 7+ earthquake near the bridge could cause severe damage, making a comprehensive seismic retrofit essential. Project Scope The retrofit was planned in three phases, ensuring seismic resilience while preserving the bridge’s historic architectural beauty: North Approach Viaduct – Strengthened to prevent the collapse of its tall support towers. South Approach Viaduct & Fort Point Arch – Included anchorage housing, pylons (S1 & S2), and energy-absorbing devices to control movements. Suspension Bridge & North Anchorage Housing – Strengthened main span trusses, tower connections, and foundations to withstand seismic forces. DYWIDAG’s Contribution Supplied and installed multistrand post-tensioning tendons and epoxy-coated multistrand tiedown anchors. Reinforced pylons S1 & S2 with steel plates and concrete coverings for seismic resistance. Strengthened foundations using 90 multistrand tendons (pylon S1) and 24 tiedown anchors (pylon S2). Upgraded South Anchorage Housing with high-strength THREADBAR® tendons. Installed shear walls and additional reinforcements in the south abutment and multiple foundation sections. Completion & Impact Construction began in 2001, with DYWIDAG’s key installations completed in August 2004. The Fort Point Arch uplift risk was mitigated using controlled lifting mechanisms. The Golden Gate Bridge remains safe and operational, now capable of withstanding earthquakes of up to magnitude 8.3. This retrofit ensures the long-term structural integrity of the Golden Gate Bridge, maintaining its role as both a critical transportation link and a global landmark.

Bridge project

Project: Pulau Balang Bridge – Overcoming Logistical Challenges The Pulau Balang Bridge in Borneo, Indonesia, connects Balikpapan Bay’s eastern side to Balang Island and is Indonesia’s longest concrete deck stay cable bridge with an 804m span. DYWIDAG’s Role: Provided 4 full-time supervisors, 12 PT Delta Engineers, and 100 team members. Overcame challenging terrain—though only 25km from Balikpapan, road transport took a full day, making boat transport essential despite capacity and safety issues. Installed first cables in October 2019, with bridge completion in November 2020. This project highlights DYWIDAG’s adaptability in overcoming extreme logistical challenges. As of January 2021, it became the 4th DYWIDAG stay cable bridge in Indonesia.

Bridge project

Project: Smart Stay Cable Upgrade for the Guadiana Bridge The Guadiana International Bridge, spanning 666m with a 324m central span, connects Spain and Portugal. After multiple strand failures, inspections in 2018 confirmed the need for a full stay cable system replacement. DYWIDAG’s Role: Inspection & testing (June – Aug 2018) Stay cable replacement (Nov 2019 – Apr 2021) The replacement involved removing old cables, modifying anchorages, and installing new DYWIDAG monitoring stay cables with sensors for continuous force measurement. The system includes elasto-magnetic sensors, cable vibration dampers, and automated force monitoring. With completion in April 2021, the bridge is now safer, stronger, and equipped with smart monitoring technology.

Bridge project

Project: “Supporting the World’s Highest Railway Bridge” A bridge was needed to connect a railway across the deep Chenab River gorge in India, posing a major engineering challenge. The Chenab Rail Bridge, located in Jammu and Kashmir, stands 359 m (1,178 ft) high, making it the world’s highest railway bridge. DYWIDAG’s Role: Supplied and installed ground anchors (May 2014 – June 2017) and temporary stay cables for arch erection (Dec 2017 – June 2021). Ensured local fabrication to prevent transport damage. Completed arch construction in April 2021 and stress-tested 56 cables by Dec 2021. Installed horizontal ties in March 2022, finalizing the arch, with cable dismantling set for fall 2022. Designed to last 120 years, the bridge can withstand winds of 266 km/h and zone-V earthquakes.

Building project

In our country, the Baku Tower is one of the projects where an earthquake and wind protection system has been implemented. The 277 m high Baku Tower project is the tallest building in not only Azerbaijan but also the entire Caucasus. The specifics of our city, known as the City of Winds, created certain corresponding challenges for the project. The structure is subjected to significant wind loads. Since Baku is located in a seismic zone, MAURER also designed a TMD (tuned mass damper) system weighing 400 tons to ensure safety. According to reports, without the damper, the structure would be displaced by 1.3 m under the most severe wind and seismic loads. With the damper, this figure does not exceed 60 cm. The customer set two important tasks to be solved. The first was to design the TMD system so that it could be lifted to a height of 250 m from the ground. The second was to quote the acceptable price. To meet the technical requirements and ensure cost efficiency, MAURER designed a system weighing 180 tons made of a steel box and 220 tons of concrete. If the entire mass were made of only steel/metal, the costs would be significantly higher. The 180-ton steel box was designed modularly to fulfill the first task. The number of TMD components reached 500, and they were delivered to the site by 15 trucks. After the 180-ton steel box was mounted at the top of the building, it was filled with 220 tons of concrete. This solution allowed the customer to save significantly.

Building project

In our country, the SOCAR Tower was one of the projects for which MAURER provided earthquake and wind protection. In this project, as in the Baku Tower, the TMD system was installed at the top of the building. The SOCAR Tower is 200.45 m high and consists of 42 floors. The structure’s height weakens its resistance to both wind and earthquakes. It is worth noting that in the project area, the wind speed sometimes reaches 190 km/h. Before the installation of the seismic protection system, the structure ‘played’ within 50 to 100 cm in strong winds, according to reports. Therefore, an earthquake and wind protection system (TMD) was installed at the highest point of the structure. Usually, a ceiling height of 10 m is required to install a TMD. However, in the SOCAR Tower project, it was not possible to provide such a height, and a space with a ceiling height of 7 m was proposed. MAURER redesigned the TMD system, making some changes to it to fit the 7 m height instead of 10 m. A solution with two TMD systems in one was chosen. The total mass was 450 tons. That mass was secured by 4 cables. The protection system installed in the SOCAR Tower project consists of 3 different safety levels. These are: Vibration protection system – the structure is strong enough not to feel small vibrations. However, despite this, a protection system against small vibrations was designed as the first level. Strong winds and storms – the second protection level was designed to deal with large amplitudes caused by strong winds and storms. Earthquakes and stronger storms – a time when amplitudes reach their maximum. Displacements of more than 30 cm are expected here. In short, the SOCAR Tower project is fully protected from earthquakes, strong winds, and storms thanks to the 450-ton TMD system and 3-level safety mechanism.

Building project

In our country, the Heydar Aliyev International Airport was one of the projects for which MAURER provided earthquake protection. The work under this project was completed in 2011. This is a reconstruction project. The new runway is over 4,000 m long, 75 m wide, and covers a total area of 325,000 sq. m. MAURER supplied 39 spherical bearings for the Heydar Aliyev International Airport project.

Building project

The new administrative building of the Central Bank is one of the projects for which MAURER provided earthquake protection. In this project, a seismic protection system was installed for a special section around the tower. When installing earthquake protection systems, MAURER designs solutions and implements products according to the project specifics. For the new administrative building of the Central Bank, spherical bearings were used in the foundation isolation system. In this project, 7 spherical bearings were installed on the ceiling of the structure located around the tower and below ground level.

Building project

One of our completed projects related to seismic protection systems in the country is the Salyan ASAN Service Center. This project was inaugurated by President Ilham Aliyev on April 18, 2023. The product used in this project consists of 12 elastomer bearings manufactured by MAURER. However, the project does not involve the seismic protection of the building itself; rather, it is installed between the building and the metal structure on top of it. There are two nuances to highlight here. The first concerns the metal structure itself. The metal structure, which rests on the 12 elastomer bearings, will move easily over the bearings during expansion and contraction caused by heat and cold. This prevents cracks from forming at the ceiling joints. The other key point is cost savings. Thanks to the elastomer bearings, significant savings can be achieved in the mass of the metal structure. This is because the required movement capability is managed by the elastomers. As the movement capability is supported by the elastomers, there is no need for the metal structure to be designed rigidly, resulting in substantial savings in the metal mass.

Bridge project

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany) for projects implemented in our country. One such project is the Barda-Aghdam motorway, which is part of the Karabakh development plan. We supply MAURER sinusoidal expansion joints and elastomeric bearings to the general contractor of this project, KORPU BINA TIKINTI LLC. The road length is 45 km, and the construction of 4 bridges is planned. The motorway is being built according to the 1st technical class and will have 4 lanes. We are proud to implement part of the Karabakh Development Plan.

Bridge project

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany) for projects implemented in our country. One such project is the Aghdam-Khindarkh-Aghjabedi motorway, which is part of the Karabakh development plan. We supply MAURER expansion joints and elastomeric bearings to the general contractor of this project, KORPU BINA TIKINTI LLC. The motorway length is 45 km, and the project involves 3 bridges (over a canal, the Gar-Gar River, and the Karabakh canal). The motorway is being built according to the 2nd technical class. We are proud to implement part of the Karabakh Development Plan.

Bridge project

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany) for projects implemented in our country. One such project is the Ahmadbayli-Fuzuli-Shusha motorway. This project is part of the Karabakh Development Plan. We supplied MAURER expansion joints and elastomeric bearings for several bridges under this project. The road is being built according to the 1st technical class and will have 4 traffic lanes, with 1 spare lane in each direction. The main part of the road has 4 lanes and a width of 21.5 m. The construction of 7 tunnels, 9 viaducts, 7 motor road bridges, and 11 underpasses is supposed in this section. ESDESCON LLC supplied MAURER elastomeric bearings and expansion joints only for bridges built by Korpu Bina Tikinti. We are proud to implement part of the Karabakh Development Plan.

Bridge project

As ESDESCON LLC, one of the projects for which we supply expansion joints and bearings from the German company MAURER is the Qubadli-Eyvazli highway project in the Karabakh and East Zangazur regions. The Qubadli-Eyvazli highway project, part of the Karabakh Development Plan, is 28.5 km long and is being constructed according to the fourth technical category. The construction works are being carried out by Protean Construction ASC. As ESDESCON LLC, we have provided a total of 108 elastomer bearings and 5 expansion joints measuring a total of 65 meters in length for the bridge projects in this project. It is an honor for us to be part of the Karabakh Development Plan.

Bridge project

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany) for projects implemented in our country. One such project is the Ahmadbayli-Horadiz-Minjivan-Aghbend motorway project. This project is part of the Karabakh Development Plan. The motorway has a length of 124 km and is being built according to the 1st and 2nd technical classes. The project involves the construction of 3 tunnels, 32 viaducts, and bridges. ESDESCON LLC supplied MAURER elastomeric bearings and expansion joints for some of the bridges on this road. We are proud to implement part of the Karabakh Development Plan.

Bridge project

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany). One such project is the Aghdam-Fuzuli motorway passing through the Aghdam, Khojavand, and Fuzuli regions. We supplied MAURER expansion joints with a total length of 96.16 m for 2 bridges under construction by the general contractor, NORTH WEST CONSTRUCTION LLC. We are proud to implement part of the Karabakh Development Plan.

Bridge project

As ESDESCON LLC, we carry out the sales of expansion joints and bearings from the German company MAURER in our country. One of the projects we are involved in is a bridge project located in the Zangilan district of Karabakh. For this bridge, which is a part of the road and is constructed by the main contractor EVRASCON OJSC, we have supplied 12 large MAURER elastomer bearings. It is a source of pride for us to be a part of the Karabakh Development Plan.

Bridge project

ESDESCON LLC supplies expansion joints and bearings by MAURER (Germany) for projects implemented in our country. One such project is the Shukurbayli-Jabrayil-Hadrut motorway project. This road is also part of the Karabakh Development Plan. We supplied MAURER expansion joints and elastomeric bearings for 6 bridges under this project. The road is being built according to the 1st technical class and will have 4 traffic lanes. In general, the project provides for the construction of 6 road bridges and 11 underpasses. The road starts in the Shukurbayli village, the Jabrayil region, and ends in the Hadrut settlement, in the Khojavand region. The road, passing through the Jabrayil, Fuzuli, and Khojavand regions, will be 39.7 km long. The image shows both the road and the bridges. We are proud to implement part of the Karabakh Development Plan.

Road project

The project shown in the pictures is located in Vietnam. The product used is the Rolling Barrier. Rolling Barrier products are used for road safety and have the function of dissipating impact forces. In this project, barrier systems with a total length of 70 m were used in 2 different areas. One of the products we sell at ESDESCON LLC, is related to road safety and traffic management. These products belong to the Korean company SHİNDO SAFETY. This project is one of SHİNDO's global projects. Since 1987, SHİNDO has been engaged in the production of products related to road safety and traffic management, with 6 different factories operating according to the specifications of the products. Main product categories: Crash cushions and end terminals Protectors with different color coatings Rolling Barrier Road safety, traffic management, and parking products

Road project

The images show a project implemented in Vietnam. The Rolling Barrier (Mash TL4) product was used. Rolling Barriers are used to ensure road safety and have the function of absorbing impact force. In this project, barrier systems with a total length of 214 m were used. ESDESCON LLC also sells road safety and traffic control products. These products are manufactured by South Korea`s SHINDO SAFETY. The above project is one of SHINDO's global projects. SHINDO has been manufacturing road safety and traffic control products since 1987. The company operates 6 different factories according to the product purpose. Main product categories: Air bearings and terminals Colored fuses Rolling Barriers Road safety, traffic control, and parking products

Building project

The images show the project of the Stuttgart Hospital in Stuttgart, Germany. The hospital has 2,000 beds and occupies an area of 93,000 m². NOEtop Wall Formwork systems were used in the project. The images show the formwork used during construction. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. These systems are used in the construction of buildings and other similar structures, bridges, and tunnels.

Building project

The image shows the project of the Klimahaus Bremerhaven museum in Germany. In the construction of this project, 1,350 m² of aluminum formwork, 4,400 m² of flooring formwork, 2,800 m² of wall formwork, 1,600 m² of staircase and elevator shaft formwork, as well as many other support systems and accessories were used. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. These systems are used in the construction of buildings and other similar structures, bridges, and tunnels.

Building project

The image shows a project of an exhibition center Edeka Arena in Offenburg, Germany. The project covers an area of 7,000 m² and is intended for not only business exhibitions but also many other purposes. The project consists of 3 structures of different heights. During the construction of this project, the following were used: 2,500 m² of NOEtop wall formwork Formwork panels of various sizes Formwork support systems, etc. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. These systems are used in the construction of buildings and other similar structures, bridges, and tunnels.

Building project

The image shows a project of the Olympic Center in Munich, Germany. Several NOE formwork products were used in this project. Those were NOEtop wall formwork 2.65 to 3.31 m high. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. These systems are used in the construction of buildings and other similar structures, bridges, and tunnels.

Building project

The image shows the Klinikum Tuttlingen Hospital project in Tuttlingen, Germany. The project involves the reconstruction of several departments and the construction of an additional hospital building. In the construction of this project, NOE flooring formwork, formwork support systems, and NOE formwork lining were used. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. These systems are used in the construction of buildings and other similar structures, bridges, and tunnels.

Building project

The image shows the Prinzenpark Düsseldorf office building project in Düsseldorf, Germany. In the construction of this project, formwork for floors, walls, and columns, formwork support systems, and formwork accessories were used. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. These systems are used in the construction of buildings and other similar structures, bridges, and tunnels.

Building project

The images show the project of the Auwald Sports Center in Bavaria, Germany. Since the facility is located on the riverbank, this aspect was considered in the facade design. The facade design was chosen from NOE catalogs and adapted to the surrounding environment. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. Along with construction formwork, NOE also manufactures architectural ones. Architectural formwork allows for creating any patterns, images, designs, ornaments, logos, etc., on concrete surfaces, which can be chosen from the NOE catalog or ordered according to an individual design. NOE, which strives to create unique designs using architectural formwork, also offers cost-effective solutions since each formwork can be used up to 100 times.

Building project

The images show a project implemented in Austria. Below are images of NOEplast used in the construction of the logistics center of the famous KTM company in Austria. In this project, the customer chose the Granit IV design from the NOEplast product catalog. This design makes the concrete look like natural stone. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. Along with construction formwork, NOE also manufactures architectural ones. Architectural formwork allows for creating any patterns, images, designs, ornaments, logos, etc., on concrete surfaces, which can be chosen from the NOE catalog or ordered according to an individual design. NOE, which strives to create unique designs using architectural formwork, also offers cost-effective solutions since each formwork can be used up to 100 times.

Building project

The project is related to retaining walls built to prevent flooding. In this project, the facades of the retaining walls were built using NOEplast masonry relief. The NOEplast product used is called Murus Romanus (translated from Latin as Roman Wall) and is an architectural formwork imitating masonry relief. Another product used is the NOECombi 70 wall formwork. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. Along with construction formwork, NOE also manufactures architectural ones. Architectural formwork allows for creating any patterns, images, designs, ornaments, logos, etc., on concrete surfaces, which can be chosen from the NOE catalog or ordered according to an individual design. NOE, which strives to create unique designs using architectural formwork, also offers cost-effective solutions since each formwork can be used up to 100 times.

Building project

The images show a project implemented in Montpellier, France. The structure is an educational and entertainment center for schoolchildren. In this project, the Camargue form liner was used. This form liner was not available in the NOE catalog; it was specially designed and manufactured for this project. As seen in the images, the concrete surface patterns resemble cane. To create this form liner, natural cane treated with special liquid chemicals to copy its texture was used. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. Along with construction formwork, NOE also manufactures architectural ones. Architectural formwork allows for creating any patterns, images, designs, ornaments, logos, etc., on concrete surfaces, which can be chosen from the NOE catalog or ordered according to an individual design. NOE, which strives to create unique designs using architectural formwork, also offers cost-effective solutions since each formwork can be used up to 100 times.

Building project

The images show the Swiss Life Arena project implemented in Switzerland. For this project, NOE supplied over 50 form liners of various shapes and sizes. A total of more than 200 form liner sections were supplied. The dimensions of the largest one: length 21.7 m, width 11.59 m, which is approximately 252 m². It is important to note one nuance here. The design combines a classic style with a textile structure. The wave-shaped design on the sides also symbolizes a curtain. In general, the project, combining classical and tent-like (according to the textile style) features, communicates a gathering place, open for the people. ESDESCON LLC represents Germany`s NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. Along with construction formwork, NOE also manufactures architectural ones. Architectural formwork allows for creating any patterns, images, designs, ornaments, logos, etc., on concrete surfaces, which can be chosen from the NOE catalog or ordered according to an individual design. NOE, which strives to create unique designs using architectural formwork, also offers cost-effective solutions since each formwork can be used up to 100 times.

Building project

The images show a project of a secondary school building in Switzerland. A unique design was created on the facade of the new building using NOEplast or form liner. As seen in the images, the form liner makes the concrete surface look like a fabric texture. The reflection of sunlight changes depending on the angle of incidence. This is due to the width and depth of the texture used. In this project, 30 different parts of formwork were used. ESDESCON LLC represents German NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. Along with construction formwork, NOE also manufactures architectural ones. Architectural formwork allows for creating any patterns, images, designs, ornaments, logos, etc., on concrete surfaces, which can be chosen from the NOE catalog or ordered according to an individual design. NOE, which strives to create unique designs using architectural formwork, also offers cost-effective solutions since each formwork can be used up to 100 times.

Building project

The images show a project of a university in the Netherlands. It can be seen that both the exterior facade of the structure and the interior use concrete surfaces with patterns. The chosen form liner represents cane patterns. According to the project design, it was painted black. Even the building’s glass was given a cane texture. The goal was to ensure design integrity and prevent full penetration of sunlight into the university on sunny days. ESDESCON LLC represents German NOE, which has been manufacturing formwork products since the 1950s, in Azerbaijan. Along with construction formwork, NOE also manufactures architectural ones. Architectural formwork allows for creating any patterns, images, designs, ornaments, logos, etc., on concrete surfaces, which can be chosen from the NOE catalog or ordered according to an individual design. NOE, which strives to create unique designs using architectural formwork, also offers cost-effective solutions since each formwork can be used up to 100 times.

Building project

One of MAURER's global projects is Marina Bay Sands in Singapore. Marina Bay Sands project is a hotel with 2,561 rooms, 120,000 m² of exhibition/conference space, a shopping mall with an area of 74,000 m², a museum, a theater, restaurants, and the world's largest atrium casino. MAURER supplied 2 types of products to ensure seismic protection of this structure. One of them is 17 spherical bearings, shown in the images. These bearings allow for the structure displacement of up to 1 m. The second product is the TMD system. At the farthest cantilever point of the structure, an entertainment club was opened. As a result, the simultaneous movement of many people led to the displacement of the entire console. To prevent this displacement, MAURER designed a vertical TMD system installed at the farthest point of the console. As the name suggests, the vertical TMD system is designed to dampen upward and downward movements.

Building project

One of MAURER's global projects is Butterfly Towers in Bucharest, Romania. It was necessary to protect this structure from both seismic and wind loads. As seen in the images, 56 hydraulic dampers were used in the building. If the height of the structure is not suitable for foundation isolation and is too small for the TMD system, this method, i.e., hydraulic rods, is used. This is the best solution for such projects since achieving a similar effect would require designing the building with greater rigidity, which would lead to significant additional costs. The building is also known as Orhideea Towers. The northern part of the building has a height of 85 m and consists of 17 floors. The southern part has a height of 64 m and consists of 13 floors. Construction began in 2015, and MAURER dampers were installed in 2017.

Building project

One of MAURER's global projects is DC Tower 1 in Austria. Under the DC name, two buildings have been constructed. Here, we consider DC Tower 1. This building is 220 m high (250 m with the antenna) and consists of 60 floors. This is the tallest building in Austria, standing 60 m higher than DC Tower 2. The architect of the building is Dominique Perrault from France. Construction of DC Tower 1 began in 2010, was completed in 2013, and opened in 2014. MAURER supplied an inertial mass damper (Tuned Mass Damper - TMD) for this project. DC Tower 1 is located in Vienna, in an area of frequent and strong winds and seismic activity. Without any installed devices, the building was displaced by 45 cm under wind forces. Therefore, MAURER equipped this project with a 300-ton TMD. The main task was to stabilize the building against displacements caused by factors such as wind, storm, and earthquake. The 300-ton mass damper starts stabilizing the building even with minor vibrations caused by these three factors. One of the innovations used by MAURER in this project is semi-active dampers.

Building project

The next global reference for MAURER is the Singapore airport with a unique neo-futuristic design, holding a special place in the world. This structure is the largest single-layer steel and glass project in the world. The indoor waterfall is also the tallest one. Water falls from a height of 40 m at a rate of 40,000 L/min. The airport covers an area of 3.5 ha, and the total area of the structure is 135,700 sq. m. It consists of 10 floors, of which only 5 are above ground. The project was developed by the famous architect Moshe Safdie, who also designed Marina Bay Sands in Singapore. MAURER installed 14 support bearings for this project. It was important to consider the unified steel and glass concept of the structure. These bearings allow the structure to withstand loads up to 8,000 kN. The bearing diameter is 1,000 mm. Construction started in 2014 and was completed in 2019. The total cost of the project amounted to USD 1.7 billion.

Building project

One of MAURER's global references is the Gazprom Arena. MAURER offers seismic isolation solutions for all types of structures, including residential buildings and towers. This stadium is one of such projects. The Gazprom Arena is located in St. Petersburg, Russia. Construction was completed in April 2017. The stadium has a capacity of 67,800 spectators. The architect of the building is Kisho Kurokawa from Japan. The total cost of the Gazprom Arena project is EUR 597 million. MAURER's main focus in this project was on creating a protection system for the structure. To achieve this, MAURER used more than 100 structural bearings manufactured using high-quality MSM technology. These bearings withstand vertical loads up to 10,000 kN and have a lifting capacity of up to 3.5 MN. As seen in the construction images, there are 8 pylons at the edges. These 8 pylons connect the entire structure, and the bearings are installed in their base points. Thanks to the bearings, the arising movements are transmitted to the appropriate supports. Here, the high-quality sliding MSM technology by MAURER plays a significant role.

Building project

One of MAURER's global projects is Roland Garros in Paris. The project covers an area of 13.5 ha and comprises 20 tennis courts. One of the key features of the tennis stadium is the possibility of continuing the game even during heavy rain. The stadium is equipped with a roof, which can open and close. MAURER installed special dampers for this roof. The goal was to achieve an instant response of the roof to the slightest vibrations and ensure the noiseless operation of the roof system. As seen in the images, the stadium roof consists of 11 girders that open during rain, ensuring protection from rain. However, this system had to operate at minimal noise levels to avoid disturbing the tennis players. The noise generated in this steel structure during the wind also needed to be eliminated. MAURER used 2 different systems for this project: TMD (Vertical Vibration Dampers) and 20 (elastomeric, spherical, and lifting) bearings. These systems eliminate metal fatigue in the structure, ensuring its durability, allowing the roof to operate at minimal noise levels during opening and closing, and ensuring seismic safety.

Building project

One of MAURER's global projects is the seismic protection of the foundations of private residential houses in the Netherlands. The project was implemented in Groningen, Netherlands. In this area, large-scale gas extraction negatively affected the soil structure. As a result of the voids formed in the rocks, the seismicity of the area increased significantly. About 150 thousand people lived in this area, and before the project was implemented, thousands of houses had already been damaged by earthquakes. The Dutch government had two ways to solve the problem with residential houses in this area. The first one was to build more durable residential houses or strengthen existing structures. The second way was to seismically isolate the foundations of residential buildings. The first project was implemented in the second way on the so-called farmhouses. The foundation of the building was isolated from the subsurface, and seismic bearings were installed between them. These SIP-D type bearings allow for structure displacement within 80 mm during earthquakes, absorbing friction energy. As a result, thanks to these bearings, the structure does not perceive vibrations during the earthquake in a dangerous form. MAURER also installed its seismic monitoring systems in this project.

Building project

One of MAURER's global projects for earthquake and wind protection is the Olympic Stadium in Helsinki. A few years ago, the stadium underwent major modernization, and the entire roof was reconstructed. One of the key tasks of the project was to perform the modernization without changing the stadium exterior. As mentioned, the entire structure had to be covered with a new roof system without changing the facade of the structure. Within this project, MAURER had to ensure the seismic safety of the structure and the new roof. For this project, 96 spherical bearings of 12 different designs were manufactured. The images show 11 specially designed lifting spherical bearings. The key specifications of MAURER bearings in this project are: Free rotation and horizontal displacement Resistance to temperatures from -36° to +50° Service life of over 50 years Compensation of vertical compression and tension forces The following key points were considered in the design of these bearings: structural protection, existing architectural conditions, strong winds, and high safety requirements.

Building project

One of MAURER's latest global projects is Felipe Angeles Airport in Mexico. The airport location area is prone to frequent earthquakes. The area of the building itself is 215,000 sq. m. Therefore, the entire structure was seismically isolated from the foundation. This airport is the largest structure protected from earthquakes in Latin America. For this project, MAURER supplied 473 SIP-DR-type bearings. These bearings had to solve the following key tasks: Reduce the horizontal acceleration coefficient from 6 to 0.1 g. As a result, the structure installed on the bearings could move freely in all directions, allowing displacement of up to 300 mm in each direction. Slow down and limit horizontal friction. Return the structure to its original state after an earthquake. These bearings withstand a vertical load of up to 151,000 tons. The service life of the chosen SIP-DR bearings is at least 50 years. The bearing diameter is 620 mm, and the height is 133 mm.

Building project

One of MAURER's global projects is The Secrets & Dreams Bahia Mita Hotel. This is the largest structure in Latin America, entirely installed on seismic bearings. This project is entirely built on 410 SIP-D type bearings, which allow the structure to displace within 500 mm. As seen in the images, it was technically impossible to install the entire structure on bearings. Therefore, the structure was divided into 4 different sections, separated by expansion joints. As a result, during an earthquake, the parts of the structure can move independently of each other. The main 4 functions of installed 410 SIP-D type bearings: The bearings isolate the building from the foundation, allowing horizontal displacement of up to 500 mm in all directions. They limit movement due to internal friction. They return the building to its initial position after an earthquake. They transfer vertical loads. The two main requirements of the project customer, AMR, were ensuring uninterrupted provision of services even during a strong earthquake and a longer service life. Both requirements were met thanks to the design, consisting of expansion joints and two-layer SIP-D bearings. The supplied products are designed for up to 100 years of service. It should also be noted that the installation of these 410 bearings allowed for saving 15% of the foundation construction costs.

Building project

MAURER provided a seismic protection system for 500 years for the largest mosque in Algeria, which is also the third largest in the world. The total area of the mosque is 400,000 m². The key goal of the seismic protection developed for this project was to fully protect the structure and people visiting the mosque from small and medium earthquakes and increase the structure's resilience to strong ones. As part of this project, MAURER supplied 246 SIP Pendulum Bearings and 80 adaptive hydraulic dampers. The bearings horizontally isolate the structure from the foundation, and the dampers ensure the possibility of horizontal displacement of the structure (up to 655 mm). The key functions of the SIP bearings: Bearing the vertical loads of the structure The sliding function of the bearings allows for horizontal displacement of up to 655 mm Isolation of the structure from the foundation Automatic return of the structure to its initial position after any seismic displacement The hydraulic dampers are installed along and across the structure. The maximum reaction force is 3,065 kN.

Building project

The Tlahuac Hospital in Mexico City is the first seismically isolated hospital in the city. For this project, MAURER supplied 243 bearings (isolators) with three different features. A brief overview of the project. Mexico City is not actually located in a seismically active zone but is built on the former lake territory. This means that this area is mainly characterized by clay soil with a high water content. Therefore, an average earthquake in this area corresponds to a strong earthquake in neighboring ones. The soil deficiencies were addressed through seismic isolation of the structure. The Tlahuac Hospital is built on a durable and huge concrete box. The hospital is completely isolated from the foundation by 243 bearings (isolators) with a diameter of 850 mm. The study and calculations related to seismic isolation have confirmed that the bearings are not required to ensure displacement of 1-1.2 m. As a result, it was decided to limit the displacement to 400 mm. Given the location, this displacement of the structure was considered sufficient. The elastomeric body of the bearings withstands a vertical load of up to 50,000 tons while ensuring the possibility of horizontal movement and helping the structure return to its initial position after an earthquake. In the summer of 2020, the structure successfully withstood a 7.5 magnitude earthquake without any issues or damage.

Building project

One of the projects where MAURER's seismic protection systems were implemented is the Alto Hospicio hospital in Chile. For seismic isolation, SIP-D (Sliding Isolation Pendulum – Double) bearings were used. The total area of the hospital is 50,000 m², it consists of three separate buildings and has three floors. The key tasks of the bearings used in the project: Ensuring the safety of people inside. Protection of the structure from earthquakes. Ensuring the continuous operation of the hospital during an earthquake. Providing cost-effectiveness compared to conventional construction engineering. The SIP-D bearings used in the project were supplied in three different sizes. The largest ones have the following parameters: 650x650 mm, height 150 mm, and weight 400 kg. A total of 212 bearings of three different sizes were used. These bearings perform 4 key functions: Isolating the structure from the foundation and ensuring horizontal displacement (±250 mm). Along with ensuring horizontal displacement, limiting excessive sharp movements due to internal friction. Return of the structure to its initial position after an earthquake. Bearing vertical loads of up to 8,000 kN.

Building project

One of MAURER's projects related to seismic protection is the installation of the TMD system on a building in Peru. The project involves the installation of vibration dampers for a 9-story administrative building of an insurance company in Peru. This administrative building has 9 floors and a height of 40 m, it is narrow, asymmetrical, and has a soft frame. Although this building is not vulnerable to wind impact, it is very susceptible to earthquakes. However, the building's owner did not agree to install additional reinforcing walls to preserve the internal architectural design. Therefore, it was required to find a solution without physical intervention in the building. The study showed that the displacement on the 9th floor of the building was 225 mm, which could lead to the building's collapse and injuries to people. A solution was proposed to add a concrete mass on rubber bearings at the very top of the building, which would work on the principle of a TMD (tuned mass damper). This was the first TMD mechanism developed with the earthquake factor in mind, rather than wind. Another advantage of the proposed mechanism was that the added mass would also serve as the building's roof, being part of its mass, which significantly saved costs for the customer. The said concrete mass has a thickness of 600 mm and dimensions of 13x11 m. Its approximate weight is 210 tons. The project used 11 rubber bearings, thanks to which the displacement was reduced to 160 mm. The height of the bearings is 300 mm, and the diameter is 500 mm.

Building project

This is one of MAURER’s numerous seismic protection projects. The project concerns the historic monument of the Triumphal Arch in Bucharest. In that project, the main requirement of the customer was to strengthen the Arch's seismic protection system. The most effective way proposed by MAURER to increase the resilience of this historic monument against earthquakes was to reinforce foundation protection. As seen in the image, the method chosen was to surround the monument's foundation (reinforced frame) with expansion joints. The details of the expansion joint developed by MAURER for this project are as follows: The total length of the expansion joint is 86 m. The width of the expansion joint is 1.25 m. The expansion joint allows for the historic monument displacement within 500 mm in all directions. Since the historic monument is located above a highway, the expansion joint can withstand an axle load of up to 40 tons from vehicles. The expansion joint ensures not only horizontal but also vertical displacement. Thanks to the expansion joints, the seismic protection system of the historic monument was enhanced. Along with the use of expansion joints, MAURER developed a special solution to cover them to preserve the exterior of the monument. During restoration and repair work, they were skillfully concealed.

Building project